Plasma Cutting PA-S45 W, PA-S70 W

Plasma Cutting From 3 to 70mm

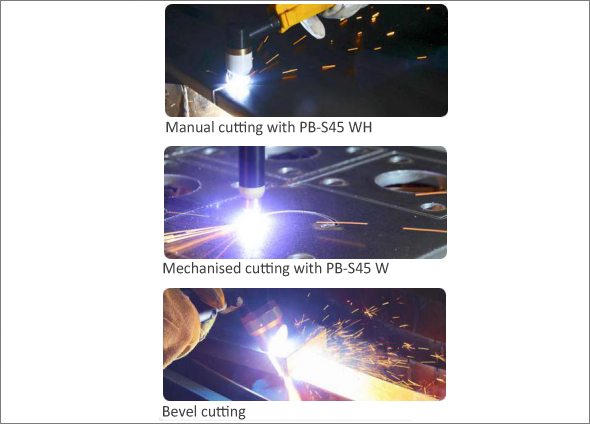

The plasma cutting systems of the PA-S series are suitable for manual and mechanised cutting of material thicknesses in the range from 3 to 70 mm. The use of a range of different plasma gases and gas mixtures allows the clean cutting and gouging of electrically conductive materials. As portable systems, they can be used in work-shops, training centres and on construction sites.

Advantages :

- Attractive price-performance ratio

- Optional use of hand or machine torch

- Suitable for 2D and 3D guiding systems

- Robust and simple design

- Portable systems for mobile use

- Reliable even under challenging production conditions

- Simple operation and maintenance with a service and diagnostic system

- Cutting current with three settings

- Fluid cooling of plasma torch for long comsumable life

- Quick switch from cutting to plasma gouging

- Angled torch heads and special shaft designs for optimised cutting of 3D parts

Advantages :

- Metal construction and engineering

- Plant and tank construction

- Pipeline engineering

- Scrap cutting

- Dismantling

An essential requirement for the quality of cut surfaces is the proven design of the torch's cathode and nozzle. The liquid cooling of the plasma fine-jet torch guarantees longer consu - mable life. Plasma cutting with the systems in the PA-S series is more efficient by increasing the productivity of the user. For the cutting of mild steel with the PA -S45W, a swirl gas torch allows more frequent piercing.