Stainless Steel Passivation Chemicals / Supplier And Exporter

What is Passivation?

Passivation is the chemical treatment process by which the electrochemical condition of passivity is obtained on the surface of metal alloys. Passivity as it relates to austenitic stainless steel is the state in which chemical reactivity is minimized under special environmental conditions, such that the metal exhibits a very low corrosion rate.

Or simply …

Removing contaminants and free iron from the surface of stainless steel, then chromium enriching the surface to form a corrosion resistant chrome oxide layer.

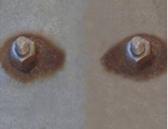

If you dont passivate the result can be . . . .

Weld and In-situ Corrosion

Post Installation Problems :

Effective Passivation Provides . . .

Critical Applications Requiring Passivation

CitriSurf® 3050 Formulation for cleaning and passivation of austenitic grades of stainless steel where very low foaming is required, i.e. systems with air agitators and CIP systems. (1 gallon makes up to 15 gallons of working solution)

CitriSurf® 2210 Gelled version for cleaning and passivation of weld joints, vertical surfaces, and large items or areas on all grades of stainless steel. (Ready to use)

CitriSurf® 2310 Gelled version for rust removal and passivation of weld joints, vertical surfaces, and large items or areas. (Ready to use)

CitriSurf® 2325 Formulation for rust removal and passivation of bulk parts, tanks, and pipe systems. (1 gallon makes up to 5 gallons of working solution)

CitriSurf® 77 Plus Formulation for rust removal and passivation in a Trigger Sprayer bottle for applications where it is desired to spray the product on a local area. (Ready to use)

Additional formulations for other applications are available in addition to these standard products.

CitriSurf® 3250

Description : CitriSurf® 3250 is a high quality blend of chemicals formulated for the cleaning and passivation of stainless steel products. CitriSurf® 3250 is a solution of chemicals specifically designed to provide low cost and efficient removal of all free iron from the surface of stainless steel. It has been specifically formulated to improve corrosion resistance and processing of the grades of stainless that are more difficult to passivate, such as ferritic stainless steels. This product also improves the speed of removal of red rust on surfaces.

Physical Properties :

| Specific Gravity | 1.22 |

| Approx. wt. /gallon | 10.2 lb/gal |

| Viscosity | 6 cps |

| Form | Liquid |

| Chemical Composition | Citric Acid, H2O + unident. ingredients |

| Operating Temperature | 120-160 Degrees F. (normal) |

| Flash Point | None |

| Water solubility | Complete |

| Normal working concentration | 9-18% by volume in water |

| pH at working concentration | 3.0-3.2 |

Packaging : Available in 5 gallon or 55 gallon plastic containers. Larger sizes are available upon request.

Application Procedure : To assure best results, the parts to be passivated should be thoroughly cleaned with an appropriate cleaning solution to remove heavy amounts of dirt or oil prior to treatment with CitriSurf® solution. All equipment, mixers, tanks and pumps should be clean and dry prior to mixing of CitriSurf® solution. CitriSurf® is an excellent cleaner by itself for many cleaning and passivation processes, but may require precleaning for heavy grease and oils.

CitriSurf® 3250 should be mixed with clean water at a ratio of 1 part of CitriSurf® 3250 with 5 to 10 parts of water by volume to fill the tank used so as to adequately cover all parts to be treated. Polypropylene, stainless steel, or equivalents should be used for construction of all tanks and devices used in the CitriSurf® bath. Agitation of the solution in the tank is recommended to attain optimum results, but is not required. Optimum results can be obtained with many parts by using this product in an ultrasonic tank.

For optimum cleaning, heat and maintain the solution temperature to 120-160°F, but your tests should best indicate the best bath working temperature for the products you manufacture. Room temperature could be adequate depending on the end use, and many applications require temperatures higher than 160°F if heat treat discoloration needs to be removed.

Completely immerse the parts to be passivated in the solution for a period sufficient to remove all free iron from the surface. This is typically 5-30 minutes, depending on temperature, grade of stainless steel, hardness, use of ultrasonics and the condition of the surface of the parts. This should be determined by testing with your product. Rinse thoroughly with clean water and dry completely in air immediately. Drying can be accelerated by use of a hot air oven or other drying medium to attain a highly passive surface.

Notes on Use : Although very safe in normal use, CitriSurf® 3250 is a Citric Acid based material, and as such it may cause irritation to exposed surfaces of the body. See Material Safety Data Sheet before using this material.

Disposal : Dispose of according to all federal, state and local regulations.

Storage : CitriSurf® 3250 should be stored at temperatures between 50°F and 95°F in 316 stainless steel or approved plastic containers (polyethylene or polypropylene).

Technical Services : For technical assistance, please contact Vishes Global at +91- 22 2859 2847/2852 3395.

Maintenance : See Maintenance Sheet for maintenance of CitriSurf® passivation bath. Specific gravity should be held to +0.010/-0.001 of initial value for normal operation.

Specifications : CitriSurf® 3250 meets all of the requirements of ASTM A-967 and AMS 2700 specifications.