Displacement Ventilation

Mehta Sanghvi is the Authorized Channel Partner for KEMPER in India

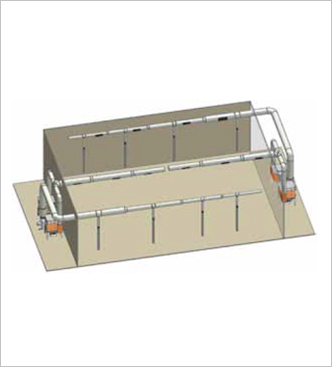

Displacement air pollution control for moderate to heavy welding fumes The displacement ventilation piping system is connected to a central extraction and filter system. It is suitable for workshops with medium to high levels of smoke and dust where a spot extractor system is not feasible, or it is used to supplement spot extractor systems. At the workplaces, the system ensures a constant, low velocity, circulating air stream.Benefits:

• Optimized, low velocity air flow by using thermal air currents

• Uninterrupted continuous operation due to automatic differential pressure-controlled filter cleaning

• Can be adapted to specific work areas due to a flexible number of outlet pipes

• Little noise emission due to a low noise level

• Heating costs minimized by air recirculation

• Convenient operation due to intelligent control via touch screen with diagnostic system

• Contamination free dust collection due to compressed air lift for duct collection container

Properties:

• Automatic filter cleaning, pressure-controlled

• Control via touch screen

• KemTex® ePTFE filter cartridges

• Dust collection container with pneumatic lifting device

• Can be connected to various extraction systems

• Can be combined with other intake systems to one extraction system

• Adaptable in line with contamination level (outlets)

• Low velocity air flow

• Economical

• Low noise level

Mode of Operation:

• Outlet pipes are installed close to the floor, inlet pipes at a height of 4-6 m and connected to a central extraction and filter system

• Contaminated, warm air rises, is collected through the inlet pipes and cleaned in the filter unit

• The purified, clean air exits from the outlet pipes at low velocity near the floor

• The warm, fresh air displaces the welding fumes towards the inlet pipes and at the workplaces a constant, circulating air stream is created

Applications:

• Medium to high levels of smoke and dust

• Workshops where local exhaust ventilation is not possible

• To complement local exhaust ventilation systems

• Environments with changing sources of smoke and dust

• For large work pieces or where work positions are well separated

• Automatic filter cleaning, pressure-controlled

• Control via touch screen

• KemTex® ePTFE filter cartridges

• Dust collection container with pneumatic lifting device

• Can be connected to various extraction systems

• Can be combined with other intake systems to one extraction system

• Adaptable in line with contamination level (outlets)

• Low velocity air flow

• Economical

• Low noise level

Mode of Operation:

• Outlet pipes are installed close to the floor, inlet pipes at a height of 4-6 m and connected to a central extraction and filter system

• Contaminated, warm air rises, is collected through the inlet pipes and cleaned in the filter unit

• The purified, clean air exits from the outlet pipes at low velocity near the floor

• The warm, fresh air displaces the welding fumes towards the inlet pipes and at the workplaces a constant, circulating air stream is created

Applications:

• Medium to high levels of smoke and dust

• Workshops where local exhaust ventilation is not possible

• To complement local exhaust ventilation systems

• Environments with changing sources of smoke and dust

• For large work pieces or where work positions are well separated