Prepmill

Signature beveler for boiler-works. Built to last!

The PrepMill series pneumatic tube facing, bevelling and weld removal machine. The PrepMill is a rugged, fast, portable weld end preparation lathe for various tubes including stainless steel and other high chromium alloys. Machine is constructed on two opposite set up taper roller bearings that makes the machine extremely stable and very rigid and compact.

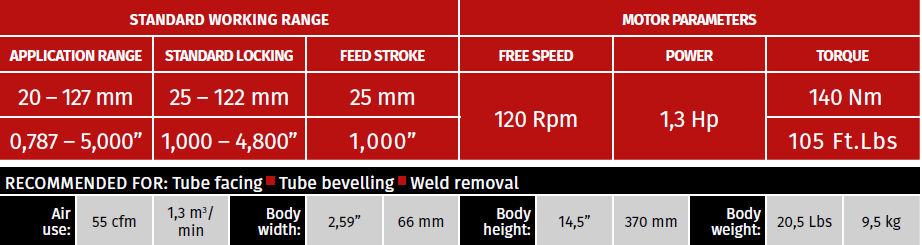

A standard machine is equipped to cover 25 to 122 mm ID (1” to 4,8”) with a 116 mm cutter head.

Key Features:

- Heavy duty rigid and powerful yet compact.

- Heavy duty ratchet handles for feeding and locking.

- Easy to lock rigidly into tube and makes continous clean chips without lubricant.

- Simultaneous bevel-face-bore machining.

- Torque free operation.

- Low maintenance and no special training is required.

PREPMILL–E

PrepMill-E is electric version of PrepMill. A standard machine can cover the same pipe sizes and comes with the same cutting head. The electric motor made by FLEX with 3 stage planetary gear box made by KRAIS has variable speed control and produce enormous torque. Is interchangeable with pneumatic drive and can be purchased separately at any time.

Free Speed................. 120 RPM

Power......................... 1500 W

Torque........................ 360 Nm (266 Ft.Lbs)

Feed Stroke................ 25 mm (1”)

AVAILABLE SHAFTS

SHAFTS 20/25

Redesigned heavy duty locking system. Shafts and jaws are longer and wider to ensure maximum clamping force. The jaws are self-align.

BACKLASH COMPENSATOR

This enables you to make the backlash compensation between shaft spline and the feed spline to ensure the machine is completely chatter free. See manual for instructions

SPEED REDUCER

Optional Speed Reducer can be used for seal and strength weld removal applications including duplex, super duplex and other hard to machine alloys.