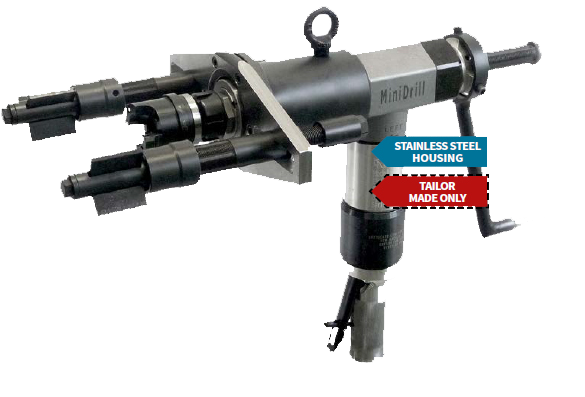

Mini Drill 80/100

MiniDrill 55 is a unique machining platform designed to safely perform multiple machining operations on heat exchangers, boilers and similar thermal exchange equipment. Designed with operator safety in mind, this system can drill, ream, bore and even re-machine serrations in steam drums quickly and safely. With a 80 mm (3.150”) travel, this tool is ideally suited for the majority of plant equipment. The system is fully torque reacted with 2 clamping arms that are independent of one another and can accommodate most pitch configurations. Once locked into the tubes, the MiniDrill is extremely stable.

WALL REDUCING

Tube wall reducing head with carbide inserts.

DRILLING

Drill for machining holes in tube plugs before removing them with our special plug removal tool

REAMMING

Safely ream tube sheets.

BORING HEAD

Boring head to machine heavy wall boiler tubes, safely and efficiently prior to collapsing through the drum.

MINIDRILL PERFORMANCE

Reducing tube wall on a 6” thick tube sheet prior to punching.

MINIDRILL WITH FAST CLAMPING

MiniDrill with the fast pneumatic clamping system is ideal for manufacturing plants that make large amounts of work on tubes and pipes. It offers rapid tube to tube cycle time, increased productivity with little operator fatigue.